HERCULES III Strongest security glass for house and condominium

Crime prevention glass strongest in Japan

HERCULES III features outstanding resistance against penetration.

Unparalleled strength, 55% higher than the strongest glass of the other manufacturers.

HERCULES III provides Class T-2 sound insulation.

HERCULES III fitted into aluminum sash was proved to meet Class T-2 Sound Insulation.

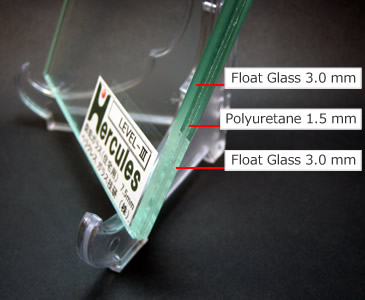

HERCULES III laminated security glass is composed of two panes of glass bonded together with resin; FL3+PU1.5 + FL3, in which FL and PU stand for "float glass" and "polyurethane interlayer" respectively. Overall thickness is 7.5mm.

HERCULES III passed the Crime Prevention Performance Test conducted by the National Police Agency of Japan, and is qualified for CP Mark. The test items include "breaking test", "torching test" and "prying test".

CP Mark is the symbol of building materials certified high grade of Crime Prevention performance.

Security Glass Mark of Flat Glass Manufacturers Association of Japan.

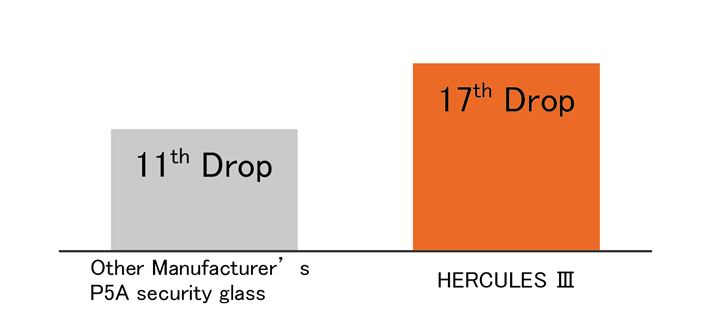

Comparison with other manufacturers’ P5A security glass

Materials for the Steel Ball Drop Impact Test:

P5A flat glass (7.7mm thick) of another manufacturer

HERCULES III (7.5mm thick)

Test Method for Steel Ball Drop Impact Resistance

The Steel Ball Drop Impact Test is to free-fall a solid steel ball (100mm in diameter, weighing 4.11Kgs) from the height of nine (9) meters above the surface of test material having measurements of 900mm x 1,100mm.

The drop points are the apexes of a regular triangle having a side length of 130mm each. The steel ball free-drops on each apex of the triangle, and the dropping is repeated three (3) times, making the total number of the dropping nine (9) times.

If the glass endures the foregoing drop impacts with no break-through at any apex, the glass is graded Class P5A in accordance with the Test Criteria of The Flat Glass Manufacturers Association of Japan.

Result of Steel Ball Drop Impact Test

HERCULES III showed outstanding performance unparalleled with other manufacturers. HERCULES III was penetrated at the 17th drop, while the other glass penetrated at the 11th drop.

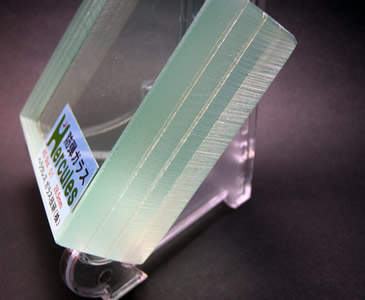

HERCULES III's Transparency

HERCULES III features 89% of visible light transmission, which surpasses those of other manufacturers.

HERCULES III's Adaptability

HERCULES III's thickness of 7.5mm makes it easily fit in the groove of the ordinary sashes of 9mm. HERCULES III weighs 17Kg/m2.

HERCULES III's Quality

HERCULES III meets the quality requirements specified in JIS R3205, including thermal resistance, light stability, weatherability, lead-shot filled bag test, etc.

Price

HERCULES III is stronger than the strongest security residential glass of other manufacturers, though the price is comparatively cheap.

HERCULES IV - Security Glass for Buildings

Crime prevention glass strongest in Japan

HERCULES IV laminated security glass is composed of two panes of glass and a polycarbonate sheet sandwiched in between, firmly bonded together with polyurethane. Overall thickness is 14mm.

HERCULES IV is granted CP Mark

HERCULES IV passed the Crime Prevention Performance Test conducted by the National Police Agency of Japan, and is qualified for CP Mark. Which indicates that the product is in the list of building materials of high level security performance.

HERCULES IV features superb impenetrability of 5 to 10 times greater than HERCULES III.

CP Mark is the symbol of building materials certified as having high grade of Crime Prevention Performance.

HERCULES IV's security performance complies with P6B classification of European Security Standard EN356, in which the glazing should endure 12 times of blows by a sledge hammer and 18 times of blows by a broad axe without penetration.

HERCULES IV's Transparency

HERCULES IV can be used for crystal-clear show window/case not tinged with green inherent to glass, if highly transmissive glass (such as PuresightTM) is used in lieu of ordinary float glass.

HERCULES IV's Measurements and Weight

Thickness: 14mm

Typical Measurements: 1.2 x 2.4m max.

Weight: 27kg / m2

HERCULES IV's Quality

HERCULES IV meets the quality requirements specified in JIS R3205, including thermal resistance, light stability, weatherability, lead-shot filled bag test, etc.

HERCULES IV's Security Performance

HERCULES IV has quite high security performance, though it does not guarantee perfect protection against burglary intrusion, as the burglary method varies on a case-by-case basis. Glazing of HERCULES IV and the installation thereof should be designed by an architect.

HERCULES V Blast-Resistant Glass (Anti-Terrorism)

Overcome grenade attack by terrorists

HERCULES V is composed of two panes of float glass and a polycarbonate sheet sandwiched in between and firmly bonded together with polyurethane. Overall thickness is 19mm.

Recently, there is growing concern over the blast caused by terrorists, bomb attacks, accidental chemical reaction at production plants or research facilities, etc. Shock waves and flames generated by blast endanger human lives, properties and facilities.

HERCULES V provides "shield against blast"

HERCULES V blocks shock waves generated by blast, and prevents damage from the shatters and fragments from the explosive.

Click to play video

HERCULES V features blast-resistant performance equivalent to that of the glass which has passed Bomb Blast - Hand Grenade HE High Explosive HG85 Test specified in Australian and New Zealand Standard AS/NZS 2343:1997.

The purpose of the blast-resistance test is to examine whether any penetration of fragments occurs by the specified detonation test which comprises two times of detonation of HG85 hand grenades; the 1st detonation on the ground and one meter distant from the glass, and thereafter the 2nd one at the height of 30cm above ground and also one meter distant from the glass.

Hercules V’s Anti-burglary Performance

Hercules V substantially endures any of burglar’s break-in attempts either by torching typically with oxy-acetylene torch, impact tools such as hammers and axes, glass cutting with disc grinder.

It takes eight (8) minutes to break Hercules V in combination of torching and impacts by experienced burglars. (In the case of the window having two crescent locks, it takes 16 minutes for breaking.) In Japan, burglars usually give up break-in attempts, if it is unsuccessful within five (5) minutes.

Click to play video

HERCULES V's Measurements and Weight

Thickness: 19mm

Typical Measurements: 1.2 x 2.4m max.

Weight: 36kg / m2

HERCULES V's Quality

HERCULES V meets the quality requirements specified in JIS R3205, including thermal resistance, light stability, weatherability, lead-shot filled bag test, etc.

HERCULES V's Security Performance

HERCULES V has exellet security performance, though it does not guarantee perfect protection against any blasts, since the acts of terrorism vary in method and so does the type of explosive. Glazing of HERCULES V and the installation thereof should be designed by an architect.

HERCULES VI Ballistic Resistance Glass (Anti-Terrorism)

Overcome bullet attack by terrorist

HERCULES VI's construction depends on the required level of ballistic resistance.

HERCULES VI offers two types of construction; multi-layered glass sheets as well as combination of multi-layered glass with polycarbonate sheets.

Since the September 11 Terrorist Attacks, there is growing threat posed by terrorists across the world. Nowadays, ballistic-resistant glass is used in military facilities, government offices, embassies, VIP residences, etc.

HERCULES VI provides "shield against projectiles"

HERCULES VI is designed to be lighter in weight and thinner than the ballistic glass of other manufacturers, while having the equivalent ballistic resistance characteristics, and to protect human bodies and properties from projectiles and debris in an event of emergency.

HERCULES VI features ballistic resistance performance equivalent to the glass which has passed internationally acknowledged ballistic resistance standards as follows:

| Standard |

Threat |

Number of shots |

Laminated Material |

| EN BR-1 |

.22 LR 40 grain lead round |

3 |

G/P |

| AS G0 |

9mm Parabellum 115 FMJ |

3 |

G/P |

| AS G1 |

.357 Magnum 158g SWC |

3 |

G/P |

| AS G2 |

.44 Magnum 240g SWC |

3 |

G/P |

| NIJ-3A |

.44 Magnum 240g SWC |

3 |

G/P |

| EN BR-5 |

5.56*45 NATO 62g SS109 (M855) |

3 |

G/P |

| AS R2 |

.30 cal. 7.62 NATO 147g M80 |

3 |

G/P |

G : Glass P : Polycarbonate panel

Click to play video

HERCULES VI's Ballistic Resistance Performance

HERCULES VI has excellent ballistic resistance performance, though it does not guarantee perfect protection against any ballistic attacks, since the acts of terrorism vary in method and so do the types of weapons. Glazing of HERCULES VI and the installation thereof should be designed by an architect.

"HERCULES A" Architectural Glass

HERCULES ATM laminated architectural glass offers outstanding performance beyond conventional architectural glass, in terms of light stability, weatherability and durability, energy-saving characteristics and so forth.

HERCULES ATM has an interlayer made of acrylic resin specifically developed for laminated glass.

HERCULES A color glass suitable for both exterior and interior applications

The standard measurements are 2m x 3m for convenience in handling.

In the case of a form factor beyond the said standard, please get in touch with HERCULES.

HERCULES A's Performance Characteristics

Superb

Transparency

| HERCULES A's clear glass provides higher transparency than conventional film-laminated glass.

|

| UV Protection |

Cutting UV radiation by more than 99%, which prevents fading of furniture and carpets, and protects human body from the risks of skin cancer. |

| Weatherability

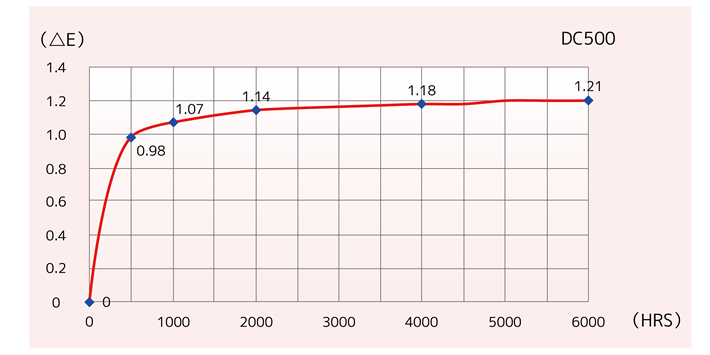

| Accelerated weathering test involving cyclic exposure to UV radiation and hot-water spray found color difference (ΔE) of 1.2% after 6000 hours of continued test by Suga Test Instruments Mfg's Sunshine Weather MeterTM.

|

| Light Stability

| Accelerated light-stability test involving exposure to temperature of 63℃, humidity of 50% and UV irradiation intensity of 100mW/cm2 found color difference (ΔE) of 3.2% after 1000 hours continued test by Iwasaki Electric's "EYE Super UV TesterTM".

|

Temperature

Cycle

Resistance

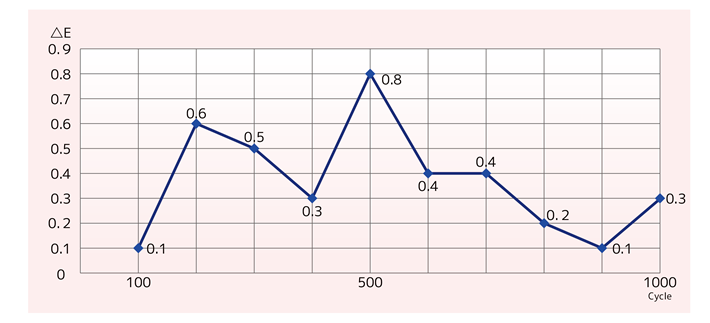

| Thermal shock test involving 1000 cycles of cooling and heating (-50℃ for 30minumtes → 100℃ for 30minutes → -50℃ for 30 minutes) conducted by Satake's "Temperature Cycle TesterTM" found the color difference (ΔE) of 1.0%.

|

| Sound Insulation

| The resin interlayer of HERCULES A functions to suppress ”coincidence effect” inherent to glass, and renders better sound insulation than conventional laminated glass.

|

| Insect Deterrent

| The resin interlayer of HERCULES A blocks the lights attracting insects (peak frequency 370nm) to keep insects away.

|

| Color Glass

| HERCULES ATM offers two types of color glass, one for exterior applications and the other for interior, thereby meets diversified requirements of architects for more aesthetic glazing and interior glass.

|

Quality Performance of HERCULES ATM Architectural Glass

Result of Accelerated Weathering Test by SWOM (Suga's Sunshine Weather MeterTM

Test Condition: Cyclic test of heating at 63℃/Spraying water for 12 minutes/Irradiation of UV rays for 60 minutes

The test result shows that HERCULES ATM is a laminated glass featuring superb weatherability.

Result of Thermal-Shock Cycle Test by Satake Chemical Equipment Mfg’s thermal-shock cycle tester

Test Condition: Cyclic test of Cooling at -50℃ for 30 minutes >> (5 minutes) >> Heating at 100℃ for 30 minutes >> (5 minutes) >> Cooling at -50℃ for 30 minutes

The test result shows that HERCULES ATM is laminated glass suitable for extremely cold places as well as scorching hot places.